Relax Group's subsidiaries include Relax Health Industry Co., Ltd. (Qingdao Industrial Park) covering an area of 44,000 ㎡, and Relax Sports Technology Co., Ltd. (Rizhao Industrial Park) covering an area of 78,000 ㎡. The smart fitness and rehabilitation system project mainly undertaken by the company is a medical and health industry project cultivated by our province's major project of converting old and new kinetic energy. The total investment of the project is 500 million yuan, and the annual output of fitness equipment is expected to be 100,000 sets.

The MES (production information management system) of the factory construction is integrated with systems such as ERP (enterprise resource planning management system) and PDM (product database management system). It has real-time analysis of production data and data-driven management decision-making capabilities, and can realize the plan , production scheduling, production, logistics, equipment, quality control and other closed-loop management of the entire process. In addition, the company strives to build a national-level "one base, three centers", namely a national-level smart fitness and rehabilitation equipment production base, a national-level smart fitness and rehabilitation equipment research and development center, an experimental center and a testing center, which will strongly support the overall development of smart fitness and rehabilitation system projects.

0532-82525088

0532-82525088

JD Mall

JD Mall

中

中

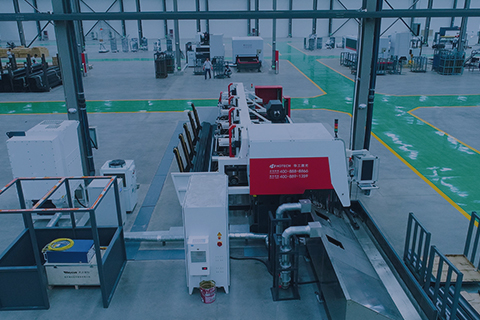

Machining Workshop

Machining Workshop

Welding Workshop

Welding Workshop

Painting Workshop

Painting Workshop

Dust-free Workshop

Dust-free Workshop

Assembly Workshop

Assembly Workshop